The Of Mapes Metal Panels

For skyscraper building indoor glazing is often made use of due to gain access to as well as logistics of changing glass from a swing stage. In exterior polished systems, glass as well as opaque panels are mounted from the exterior of the drape wall. Exterior glazed systems require swing phase or scaffolding accessibility to the outside of the drape wall for repair work or replacement.

Usually, pressure-equalized rain screen systems offer the highest possible levels of resistance to air and water seepage, with water-managed systems the following most trusted. decorative infill panels. Pressure-equalized rain screen systems work by obstructing all of the forces that can drive water across a barrier. See the post on Dampness Protection for a total explanation of how pressure-equalization withstands water passage.

All About Infill Panels For Windows

The outdoors face of glass, outside glazing materials as well as the external subjected face of aluminum framing feature as a rain display, shedding water away. In between the outside rain display as well as the indoor air barrier a pressure-equalization chamber is formed in the glazing pocket, which serves to reduce water penetration by getting rid of (matching) the stress distinction throughout the rainfall screen that has a tendency to require water right into the system.

Water-managed systems appear similar initially glance, integrating drains and weeps from the glazing pocket, yet no effort is made to create an air obstacle or "zone-glaze" each glass or spandrel unit, and also as a result a larger amount of water is pushed into the system as well as has to be cried away. Also, because no air barrier exists, the pressure differential between the glazing pocket as well as the inside might be strong enough to force water vertically greater than indoor gaskets, causing leaks.

Crying of water is just a second feature. Note that the easiest method to identify a pressure-equalized rainfall display system is yo note that the that polishing pocket around each specific unit of glass is isolated air tight from surrounding systems, a lot of certainly with plugs or seals at the voids between screw splines at mullion junctions.

Some light weight aluminum curtain wall systems are still developed as face-sealed barrier wall surfaces. They depend upon continuous as well as ideal seals between the glass units and the framework and between all frame members to do. The long-term integrity of such seals is extremely suspicious as well as such visite site systems should be prevented. Total curtain wall surface thermal performance is a function of the polishing infill panel, the framework, building behind opaque (spandrel and column cover) locations, and also the perimeter information.

Top Guidelines Of Lightweight In Fill Panels

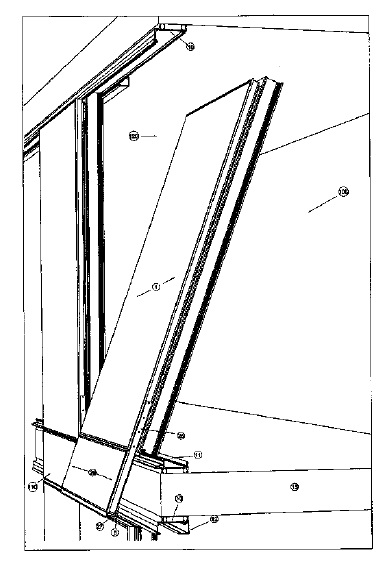

These systems frequently consist of gaskets that are positioned between the pressure bar and mullions as well as feature as thermal breaks as well as aid with acoustic isolation. These systems require unique treatment in style as well as building to make sure connection of the gaskets at horizontal and also upright changes. Gaskets are additionally used to support the glass on the inside and also outside faces of the glass (aluminium window infills).

There is usually a space in the gasket at the edges after shrinking occurs. With a correctly designed system the water that enters the system at the gasket edges will certainly weep out through the breeze cover weep openings. To reduce shrinking of gaskets back from the corners the usage of vulcanized corners as well as external glazing panel diagonally cut splices are suggested.

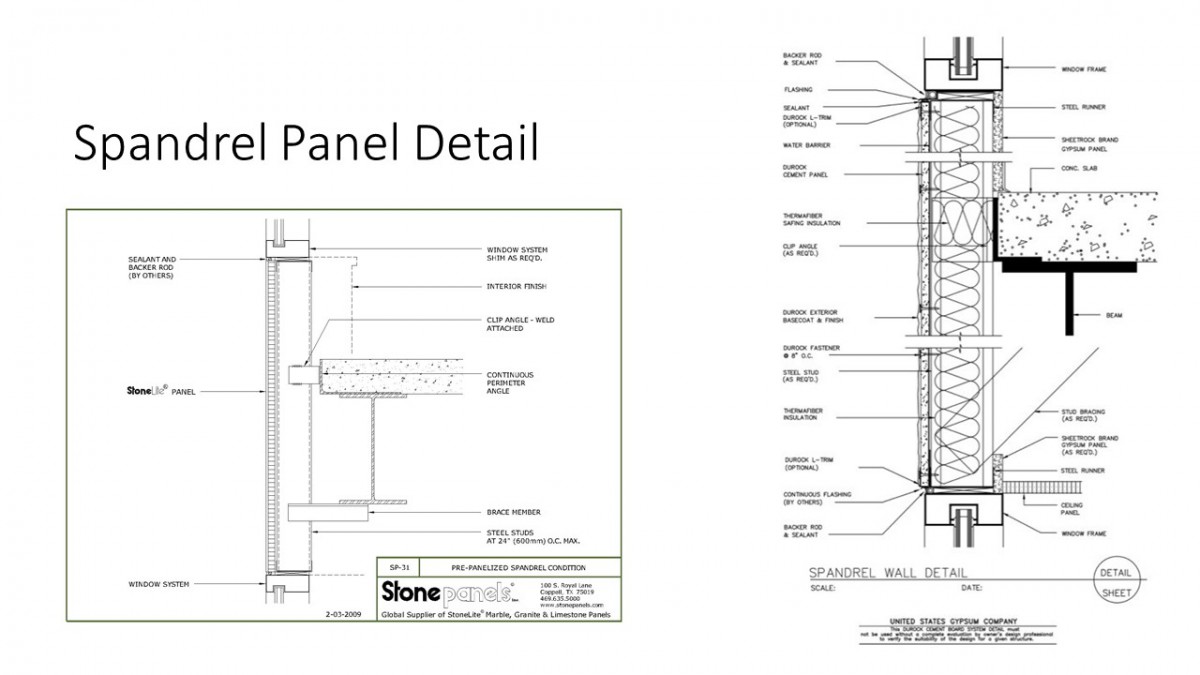

Because of the lack of interior air beside nontransparent curtain wall areas, these locations are subject to wide swings in temperature and also moisture and require mindful outlining of insulation and air/vapor obstacles to minimize condensation. Some drape wall surface systems consist of condensation drainage stipulations, such as condensate seamless gutters, that are intended to gather as well as weep condensate from spandrel locations to the exterior; such navigate here condensate seamless gutters as well as weeps are an infraction of the air barrier of the drape wall surface unless they are outboard of the backpan.

At the curtain wall border, keeping connection of the air obstacle reduces airflows around the curtain wall - spandrel panel. Assimilation of boundary flashings aids guarantee water tight efficiency of the curtain wall and its link to surrounding wall elements. Correct positioning of insulation at the drape wall border reduces energy loss and prospective condensation problems.