Unknown Facts About Decorative Infill Panels

Table of ContentsAll about Aluminium Door Infill PanelsTop Guidelines Of Door InfillUnknown Facts About Decorative Infill PanelsAluminium Window Infills Can Be Fun For Everyone

presents a new panel item for our insulated panel product line:, our Factory made Spandrel Pan that includes mineral wool, and is created to save energy in nontransparent glazing locations of exterior building envelopes. Mineral wool insulation in the spandrel pan can withstand temperature levels above 2000 F, is moisture resistant, offers acoustical noise damping, and gets approved for LEED Green Structure Credits (glass infill panels).InsulSAF M5000 Spandrel Pans can also be produced with 3000 Series Aluminum Alloys. Pan insulation is secured by resistance welded pins. Customized SAF Spandrel Pans can be arranged to get here on website ready for installation. They connect to the cladding frame work utilizing standard mechanical fasteners. Include SAF on your bid list for plate architectural items.

Chromatics monolithic spandrel panels are perfectly flat, without any roller wave, pinholes or show through. Any RAL colours are readily available, or we can exactly match your corporate colours, and print images with remarkable depth of colour and clarity. Our high-definition digital printing procedure produces long lasting, UV-resistant colours that remain intense and vibrant for the life of your curtain wall panels (aluminium infill panels).

Drape wall and storefront glazing systems are usually a thin, non-structural external faade element of a structure that can span several floors or be integrated into a punched opening. Glazing systems work mainly as air and water vapor barriers, resisting air or water infiltration and accommodate building and system movement induced by wind, thermal, and seismic forces.

Fascination About Curtain Wall Metal Panel Infill

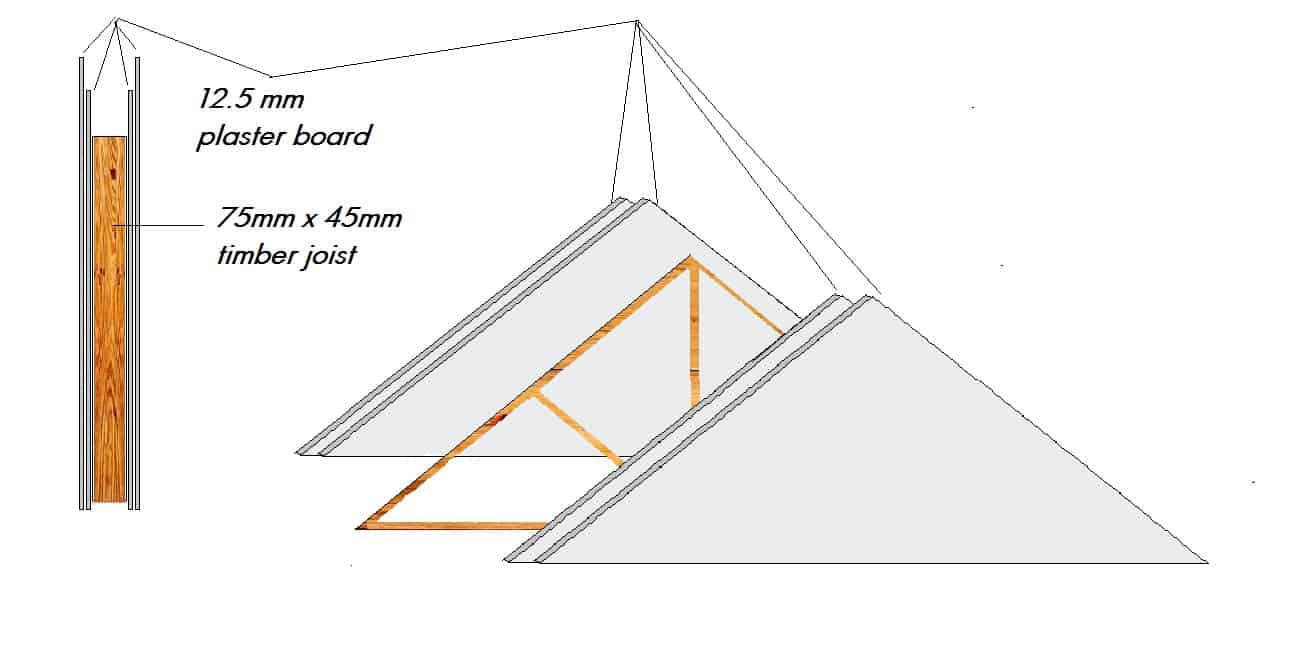

As such, light-weight products can be utilized in their development. Business glazing systems are typically built of aluminum-framed walls with glass, metal panels, louvers, operable windows or vents, or stone veneer infills. Building envelope specialists will often recommend designers on curtain wall and shop requirements for building movement, thermal expansion and contraction, water diversion, and thermal effectiveness.

Opaque glazing, metal panels, MCM (metal composite materials) panels, or insulated laminated panels are generally utilized as spandrel infill. When insulation is made use of inboard of the spandrel infill, an air area is regularly presented to avoid thermal damage to the spandrel infill. Unfortunately, the air space can offer a chance for condensation to form on the interior face of the spandrel infill.

Condensation formation on spandrel infill is probably to occur during severe winter season conditions when insufficient heat is provided from the interior to prevent interior infill surface area temperature levels from staying above the humidity. When interior surface temperatures dip listed below the humidity, water particles start to form on the interior surface area of the spandrel infill.

Should badly created spandrel conditions be left ignored, condensation can result in moisture or visual damage to the spandrel panel and/or interior surfaces. When condensation types at the spandrel infill of a glazing system, several types of damage can take place, and the results of condensation can be far-reaching. In addition to moisture damage and microbial growth, condensation development on spandrel infill can also have a negative result.

Some Known Incorrect Statements About Glass Infill Panels

This wetness can be soaked up by the surrounding components, causing damage to the assembly and nearby surfaces. As condensation develops in these unventilated locations, microbial development may develop and infect surrounding areas, triggering more damage. Condensation accumulation in these areas can damage glazing spandrel finishes. In addition, combinations of these kinds of damage can take place, triggering progressive damage that will need professional remediation.

One way to postpone the formation of condensation on the glazing system spandrel infill is to use the building HVAC system. By increasing air flow near these areas, more heat will be moved to the assembly and increase interior surface temperatures. Another way to make use of the HVAC system is by reducing the interior relative humidity Bonuses set points with respect to outside temperature.

Another approach of preventing condensation is by sealing the horizontal-to-vertical mullion joints at the spandrel cavity to avoid unrestrained air migration into the cavity. Generally, an unrestrained interior is moisture laden and when it comes into contact with the spandrel infill, which is listed below the dew point, it increases the quantity of condensation development.

In addition to integrating rehabilitation methodology, ways to lessen condensation potential throughout design include: Normally curtain wall systems have greater resistance to condensation than store systems. Utilizing drape wall is one way to reduce, or delay the beginning of condensation formation. At Pie, we provide 2-D thermal modeling (THERM) to help our customers with the style of spandrel locations.

The 25-Second Trick For Decorative Infill Panels

By understanding surface temperatures, Pie is able to identify under which conditions condensation will occur, along with determine transition points at which condensation will not develop, making it easier to predict and remediate. In addition, different setups can be modeled to take full advantage of interior surface area temperature levels. Installing back pans into the spandrel infill glazing pocket, which are vented to the outside with insulation outboard of the pan, promotes increased interior surface temperatures with the included benefit of reducing heat transfer through the spandrel infill.

It is possible to make the most of interior surface area temperatures by removing the use of insulation at the spandrel infill place. Keep in mind if you More Info develop without insulation at spandrel infill areas, there will be a greater energy loss through the assembly and for that reason larger HEATING AND COOLING heat loads. At Pie, we can help you each step of the method, whether you recently discovered condensation and are searching for removal and management options, or whether you are designing a building and goal to reduce the capacity for condensation at spandrel infill locations.